The Air Force Is Trying To Make Jet Fuel Out Of Air And Water: Here's How

Accounting for nearly 3.5% of total CO2 emissions worldwide, the need for efficient, sustainable air fuel is ever-increasing, driving innovation across industries to develop solutions. In an exciting collaboration between the U.S. Air Force and Air Company, we might be the closest we have ever been to achieving a breakthrough in aviation fuel technology.

The New York-based startup has received a $65 million grant from the Air Force's Defence Innovation Unit, fueling a project dubbed SynCe (Synthetic Fuels for the Contested Environment). In a process resembling Photosynthesis, the project aims to produce synthetic jet fuel using just water and carbon dioxide present in the atmosphere.

Air Company has already found success in extracting CO2 and utilizing it in commercial products such as their 80% ethyl alcohol hand sanitizer, carbon-negative perfume, and finally, the undeniably more exciting vodka. It claims that, as a standalone replacement for kerosene that doesn't need to be blended with fossil fuels, its AirMade fuel can cut greenhouse gas emissions by up to 97%. If this is authentic, cost-effective, and scalable, it could be groundbreaking, but many technological leaps of this kind end up encountering issues that make them impractical.

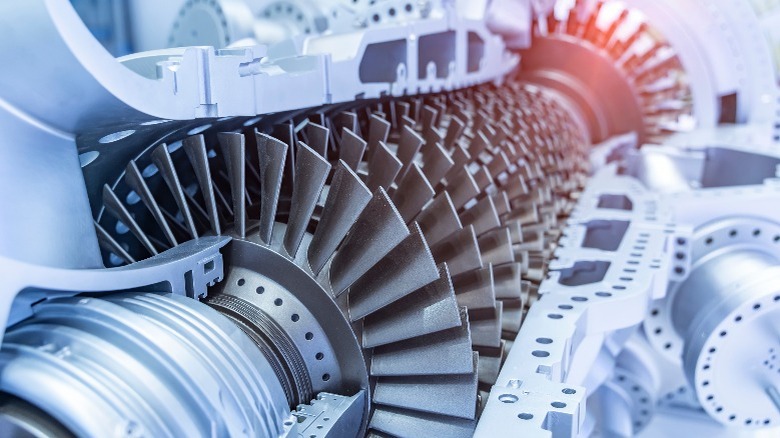

How it works: the science behind SynCe

Inspired by the mechanics of the Fischer-Tropsch process, Air Company has adapted this nearly century-old technique of synthetically producing hydrocarbons such as gasoline or kerosene from carbon. Although alternative biofuels achieve a reduction in emissions between 60 and 80%, SynCe's ambitions push the already staggering 90% benchmark of the Fischer-Tropsch-based PTL-FT process even further.

The process begins with capturing CO2 from industrial plants before it is emitted into the air. The CO2 gas is cooled, pressurized, and liquified. Using on-site electrolysis, Air Company extracts its own hydrogen from water (H2O). At the heart of the operation is the carbon conversion reactor, where the CO2 and H2 undergo a chemical reaction in the presence of a catalyst.

The reactor spews out a liquid comprising alcohols, alkanes, and water. The required alkanes are separated from water through simple distillation at different boiling points, resulting in the production of ethanol, methanol, and paraffins. Through this efficient cycle of capturing, electrolyzing, catalyzing, and distillation, Air Company aims to cut down more than 4.6 billion tons of CO2 annually, accounting for 10.8% of global emissions.

Greener skies ahead?

Transitioning from producing vodka to one of the most efficient jet fuels in the world might seem like a giant leap, and there are indeed many challenges and considerations along the way. However, with strong backing from the U.S. Air Force and Air Company's proven technological marvels, this ambitious venture has a solid foundation and incredible potential.

Popular Mechanics reports that the startup has already secured commitments from big names in the aviation industry, including Virgin Atlantic, Boom Supersonic, and Jet Blue. Skepticism arises largely from the scalability of Air Comapny's technology due to the sheer volume of fuel required by military aircraft. Facilities, including an innovation center, a factory, and a lab focused on research and development, spanning nearly 8,000 sq ft., instill faith in the project's commitment to sustainable aviation fuel technology.

"We have an incredible opportunity to reduce our burden on global energy supply chains, and simultaneously reduce emissions, without sacrificing mission effectiveness," says USAF Lieutenant Colonel Nicole Pearl, the Operational Lead at Project SynCe. With growing emissions and the effects of global warming creeping in, perhaps this scientific wonder is what the world needs right now.